ECOPACK Paper Bag with Window – Food-Contact Appropriate, Brand-Ready & Eco-Minded

The ECOPACK paper bag with window is a versatile bottom-pouch designed to align with food conservation and food-contact requirements*. Crafted from 80–100 g/m² kraft paper and fitted with a transparent window, it offers a clean showcase for products while protecting freshness. Available in variable formats, ECOPACK is ideal for biscuits, gummies, sweets, flour, tea and other dry goods.

80–100 g/m² kraft Transparent window Bottom pouch Food-contact appropriate Variable formats Custom printing

Request a quoteWhy ECOPACK?

- Visibility that sells: the clear window lets customers preview texture, shape, and fill level at a glance.

- Food-minded build: paper and adhesives selected for direct food contact suitability (dry foods) when used as intended.

- Efficient on the counter: a bottom pouch base stands more easily for clean, quick filling.

- Scalable formats: choose from compact snack sizes to larger pantry packs.

- Easy to brand: the white or natural kraft surface welcomes labels or print.

*Compliance note: Food-contact rules vary by region and application. Always verify your final specification and usage against the regulations that apply to you.

Materials & Construction

Kraft Paper: 80–100 g/m²

ECOPACK uses food-packaging grade kraft with a grammage between 80 and 100 g/m², balancing tear resistance, fold crispness, and printability. The surface accepts common print methods and self-adhesive labels for agile branding.

- Grammage range: 80–100 g/m² (nominal)

- Color options: natural or white kraft (availability may vary)

- Texture: smooth, uniform, suitable for retail presentation

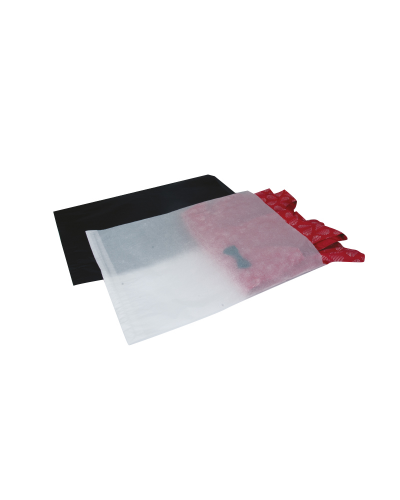

Transparent Window

A clear viewing panel is integrated on the front panel to display the product. The window helps customers confirm freshness and variety (e.g., cookie types, tea blends, gummy shapes) without opening the pack.

- Position: front panel (standard)

- Purpose: visibility & quick identification

- Care: avoid scratching; pack product gently to maintain clarity

Recyclability of paper-window combinations can vary by country. Follow local guidance on disposal, and separate components if required.

Bottom Pouch Structure & Formats

ECOPACK features a bottom pouch (block-style base) that helps the bag stand during filling and display. Side folds expand to accommodate irregular shapes and stacked items, improving volume use and shelf presence.

- Stable base aids hands-free loading on counters

- Side folds adjust capacity for bulky inclusions

- Folds flat for compact storage and transport

Indicative Size Guide

Dimensions are illustrative; actual formats supplied may differ by SKU. Always validate with your product.

| Format | Approx. Internal (W×H×D) | Typical Fill (dry) | Common Uses |

|---|---|---|---|

| XS | 80 × 140 × 40 mm | 30–80 g | Loose tea, seasoning, candy tasters |

| S | 100 × 180 × 50 mm | 80–150 g | Gummies, shortbread, nuts |

| M | 120 × 220 × 60 mm | 150–300 g | Cookies, granola, flour samples |

| L | 140 × 260 × 70 mm | 300–500 g | Biscuits, pasta nests, rice |

| XL | 160 × 300 × 80 mm | 500–800 g | Bulk treats, larger tea blends |

Perfect For

- Biscuits & cookies (shortbread, speculoos, macarons shells)

- Gummies & sweets (jellies, hard candy, marshmallows)

- Bakery & dry mixes (flour, sugar, cocoa powder—use liners if greasy)

- Tea & herbal blends (loose leaf, fruit infusions)

- Snackables (nuts, crackers, dried fruit)

Branding & Merchandising

- Front panel above/below window reserved for logos and claims

- Back panel for ingredients, nutrition, and origin statements

- Use matte labels for premium look; ensure strong adhesion on kraft

- Keep design clear around the window to let the product shine

Photography tip: soft side-lighting reduces glare on the window and keeps the paper texture rich and natural.

Closure & Filling Guidance

- Filling: open base fully and square the bottom before loading for stability.

- Sealing: compatible with labels, adhesive tape, or heat-sealing if your selected film/paper spec allows. Tin-tie or clip closures may be used as operational add-ons.

- Protection: for oily or moist foods, add an inner wrap or liner appropriate to your product and market rules.

- Storage: keep flat, cool, and dry; avoid humidity that can reduce stiffness and clarity.

Important: Do not overfill above the window edge; this protects the viewing panel and keeps the pack profile tidy.

Sustainability & End-of-Life

ECOPACK is primarily paper-based. Where local facilities permit, paper components can often enter the paper recovery stream. Combined paper+window packaging may require separation or may be handled differently by region.

- Reuse bags for secondary storage where possible

- Flatten after use to save space in collection bins

- Consult local guidance for window separation

Quality & Compliance

Materials are selected for direct food contact suitability for intended dry-food uses. However, final compliance depends on your specification, product, and jurisdiction. Conduct migration and suitability checks as required.

Good to know: Paper weight (80–100 g/m²) is chosen to balance sturdiness with flexible forming and printing.

Technical Specifications

| Product name | ECOPACK Paper Bag with Window |

|---|---|

| Structure | Bottom pouch with side folds |

| Material | Kraft paper 80–100 g/m² (nominal), food-packaging grade |

| Window | Transparent viewing panel (front) |

| Food contact | Appropriate for direct contact with intended dry foods (verify per market) |

| Formats | Variable sizes (see guide above); custom runs subject to feasibility |

| Branding | Printable paper surface; compatible with pressure-sensitive labels |

| Closures | Labels/tape; heat-seal or accessories depending on selected spec |

| Storage | Flat, cool, dry; protect from humidity and direct sunlight |

| Use cases | Biscuits, gummies, sweets, flour, tea, snacks, dry ingredients |

Frequently Asked Questions

Is ECOPACK suitable for direct food contact?

Yes, the bag is appropriate for direct contact with food when used as intended for dry foods. Always validate against your local regulations and your product’s specific needs.

Will the window compromise recyclability?

Paper-window combinations may be collected differently across regions. Some programs accept them together; others request separation. Follow local guidance.

Can I heat-seal the bag?

In many specs, yes—heat-sealing is feasible depending on the selected film/paper combination and your sealing equipment. Test on production-equivalent samples.

What grammage should I choose?

80 g/m² suits lighter fills and small formats. 90–100 g/m² supports bigger formats or heavier loads. Always test with your product and logistics flow.

Does the window fog with warm products?

Condensation can occur if warm product is packed. Let items cool to ambient before sealing to maintain clarity.

How do I keep oil stains from showing?

Use an appropriate inner wrap or grease-resistant liner when packing oily, buttery, or high-fat foods.

What’s the max load per bag?

It depends on format, product density and handling. As guidance, XS–M formats typically carry 30–300 g of dry goods; L–XL 300–800 g. Validate for your scenario.

Fast Packing Workflow

- Square the bottom and pre-crease side folds for stability.

- Insert a tray or filler scoop to guide product past the window.

- Load heavier items first; center weight over the base.

- Tap gently to settle contents to just below the window top.

- Apply closure (label/tape/heat-seal) and date/batch code as needed.

Good to know: Keeping headspace above the window protects clarity and improves shelf aesthetics.

ECOPACK vs. Opaque Paper Pouches

- Window advantage: instant product identification, less need for large imagery.

- Marketing: leverage natural product colors as a key visual.

- Operational: slightly more care needed to avoid scratching the clear panel.

Common Mistakes to Avoid

- Filling while products are still warm (condensation risk)

- Overfilling above the window edge

- Skipping adhesion/print tests on final paper stock

- Storing in humid rooms (paper waviness, label lift)

Summary

ECOPACK is a food-contact appropriate paper pouch with a transparent window and a bottom-pouch base, built from 80–100 g/m² kraft. It combines shelf appeal with practical filling, variable formats, and easy branding—perfect for biscuits, gummies, sweets, flour, tea and other dry goods. Validate the exact specification with your market’s regulations to enjoy a reliable, attractive, and eco-minded pack.